About The Steel Material for The Cranes

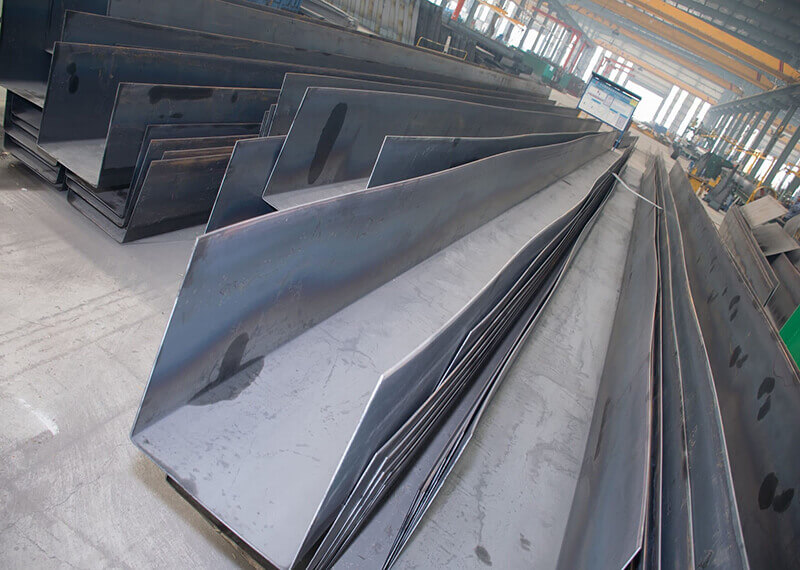

During our contact with customers, we noticed some times, our customers have special requests for the crane steel materials, here we give some brief introduction about the 2 kinds steel material will be used in our cranes.

Q235 and Q355, these are the steel material which widely used in the fabrication of our cranes.

The difference of the 2 kinds materials:

1.The yield strength:

Yield Strength for Q235: 235MPa

Yield Strength for Q355: 355MPa

2.The alloy content is different

Q235: Carbon structural steel

Q355: Low alloy structural steel

Q235--metal structural parts, carburized or cyanide parts with low core strength requirements, tie rods, connecting rods, hooks, coupling, bolts and nuts, sleeves, shafts and welded parts.

Q345--Good comprehensive mechanical properties, low-temperature performance is good, good plasticity and weldability, as metal structural parts used for medium and low-pressure containers, oil tanks, vehicles, cranes, mining machinery, power stations, bridges and other structures, mechanical parts, and building structures that bear dynamic loads, hot-rolled or normalized use, can be used for various structures in cold areas below -40 ℃.

Customer can choose the steel material they want according to the working demands:

If the cranes are working in the area with low temperature, or the working class of the crane is very high(such as A6 or A7, A8 in ISO standard), or the crane structure is rigidity control, then the Q355 steel plate will be the best choice for the customer.

If customer have no special requests, then they can choose Q235 steel plate, it's also very good in the application and its cost is cheaper compared to Q355.

We have rich experience in the crane design, manufacture and supply to customers in China or overseas, we will offer the most suitable solution to every customer!