ELECTROMAGNET FOR CRANEMANUFACTURER

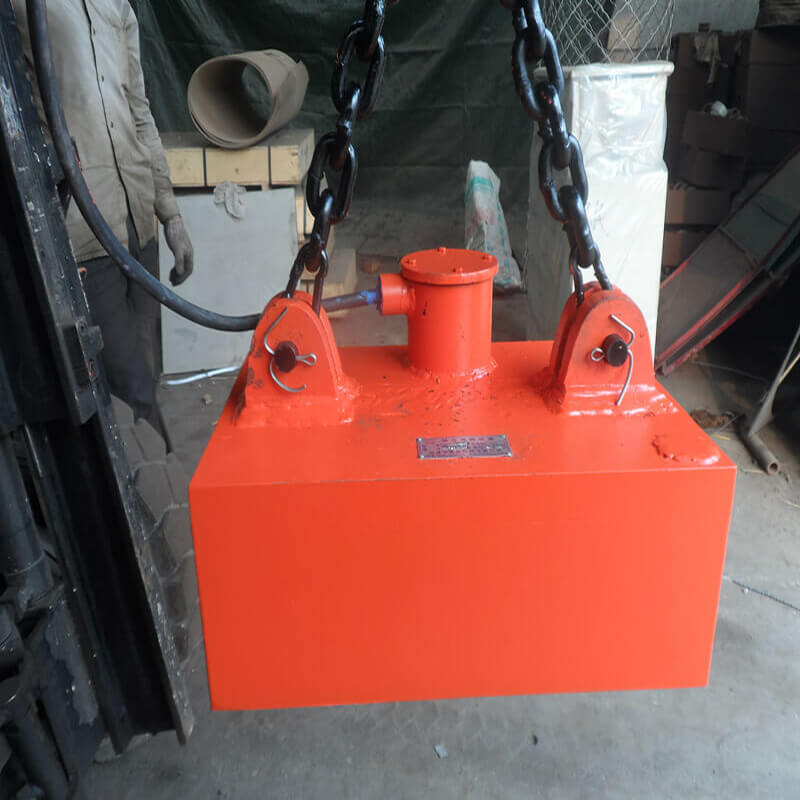

$0.00Crane lifting electromagnet introduction

Lifting electromagnet is the use of electromagnetism to handle ferro magnetic materials. Lifting electromagnet matched with various cranes to provide ideal material handling solution for materials such as steel, iron, ship manufacturing, heavy machinery, steel warehouses, ports and railways field, etc.

Lifting electromagnet is the ideal choice to lift ferro magnetic materials. It will free people from dangerous, grim and heavy working environment, such as, extremely high or low temperature, highly toxic, underwater, dusty places, etc.

DQCRANES can provide you customized services to meet various requirements in various applications. As a professional material handling solution provider, DQCRANES promises to provide the optimal material handling equipment to your application with the most cost-effective price.

Factors influencing lifting capacity of electromagnet

The lifting capacity of electromagnet is influenced by the following factors:

Surface conditions of electromagnet.

Material to be lifted

Thickness of load to be lifted

Contact surface of electromagnet on lifted load

Bending of the lifted load

Temperature of the lifted load

Stacking of the lifted load

How to select lifting electromagnet for your crane

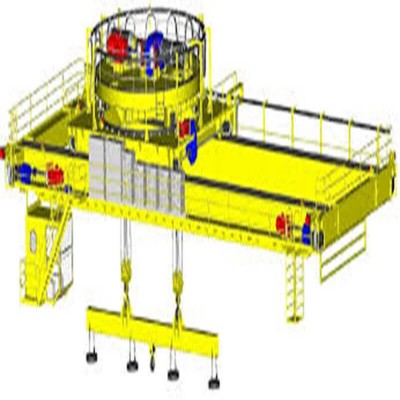

How to select the right lifting electromagnet for your crane? Several technical parameters of your crane and the handling materials need to be confirmed before the selecting of electromagnet.

Crane specifications. The main parameters of your crane needs to be provided, such as, the lifting capacity of crane, etc.

Handling materials specifications. The features of handling materials, taking billet for example, the length, volume, weight, regular temperature, etc.

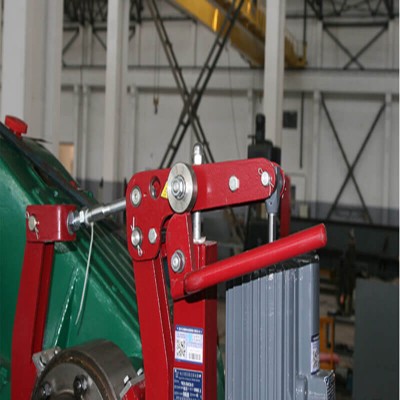

Control cabinet. Selection the control cabinet: ordinary type, blackout magnetic type, or adjustable magnetic type.

Inverter needed or not? If band-type brake is direct current, inverter is not needed or the inverter may be needed. Consult crane engineer for free now.

Specifications of electromagnets. Specifications and meanings of all kinds of electromagnets

Notice to use

Check the welding joint on non-magnetic guard board and other welding joint regularly.

Check the connecting box and cables regularly. Any problem detected should be repaired or the problematic item should be replaced in time.

Check the electromagnet insulation resistance and coil dc resistance regularly and repair it when necessary.

Check the situation of electric control equipment regularly.

Attention to the electromagnet working current in thermal state. When the working current exceeds the normal current, the operations should be stopped and inspection is needed.

Keep current voltage pressure stable, and diamagnetic link work normally and avoid the high and middle voltage impact the current coil.

The use of electromagnet should obey the operation instruction, and please do not change the on-load factor.

Electromagnet should be used in the allowable condition.

Contact Supplier

LINKS : Dongqi Crane