200kg Truss Jib Crane Intelligent Automatic Manipulator Industrial Robot

$11000.00200kg Truss Jib Crane Intelligent Hoist Automatic Manipulator Industrial Robot Lifting Equipment

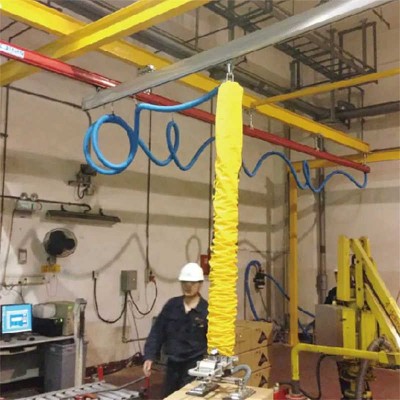

Jib Crane This remarkable Jib Crane is engineered as a state-of-the-art manipulator equipped with a cable system. It achieves seamless lifting operations by integrating auxiliary lifting mechanisms on the mechanical arm, connected via a highly flexible and durable soft cable.

Designed for versatility, this equipment partners with a variety of non-standard fixtures to perform tasks such as workpiece handling, palletizing, and loading and unloading. Not only does it significantly decrease operator fatigue, but it also optimizes productivity while ensuring superior safety in the workplace. Its adaptability makes it an indispensable tool on modern production lines across industries.

CORE TECHNOLOGY

The cutting-edge Jib Crane is composed of three main components: a robust column paired with a cantilever arm, advanced auxiliary lifting equipment, and customizable non-standard fixtures.The auxiliary lifting equipment is comprised of: Electric hoist, intelligent auxiliary elevator, and pneumatic balance hoist:

1. The Electric hoist boasts a dual-speed control mode. It offers a cost-effective, straightforward installation and operation, and requires minimal maintenance. Perfectly suited for factory warehouses and similar environments.

2. The Intelligent auxiliary elevator integrates servo drive components, a servo motor, and a reducer. It is microprocessor-controlled to intuitively follow the operator's power input, providing variable speed handling within the rated capacity. It excels in ease of use, precision, intelligent speed control, and unparalleled safety and reliability.

3. The Pneumatic balance hoist delivers comprehensive suspension capabilities within its free stroke, facilitating precise load positioning and easy operation for seamless assembly tasks.

PARTS AND STRUCTURE

1. Column

2. Cantilever arm

3. Auxiliary lifting hoist

4. Handle

5. Tooling Structure

MODELS FOR REFERENCE

1. Electric hoist

| NAME | BMS125 | BMS250 | BMS500 | BMS1000 | BMS2000 |

| Maximum load(Kg) | 125 | 250 | 500 | 1000 | 2000 |

| Lifting speed (m/ min) | 8/2 | 8/2 | 8/2 | 4/1 | 4/1 |

| Motor power(Kw) | 0.4/0.1 | 0.4/0.1 | 0.4/0.1 | 0.75/0.2 | 1.5/0.37 |

| Lifting Medium | Chain | ||||

| Power supply | 220-460V | ||||

2. Intelligent auxiliary elevator

| NAME | IAD-H80 | IAD-H200 | IAD-H300 | IAD-H600 |

| Maximum load(Kg) | 80 | 200 | 300 | 600 |

| Handle-Lifting speed-unloaded (m/ min) | 40 | 30 | 15 | 7.5 |

| Float-Lifting-speed-unloaded (m/ min) | 36 | 27 | 13.5 | 6.75 |

| Maximum stroke (m) | 3.5 | 3.5 | 3.5 | 1.7 |

| Lifting Medium | Wire rope | |||

| Power supply | 220V±10% 50HZ | |||

3. Pneumatic balance hoist

| NAME | BW005060 | BW015080 | BW020120 | BW032080 | BW035080 | BW050080 |

| Maximum load(Kg) | 22 | 68 | 90 | 147 | 158 | 227 |

| Maximum stroke(m) | 1.5 | 2.0 | 3.0 | 2.0 | 2.0 | 2.0 |

| Lifting medium | Wire rope | |||||

| Power supply | Air pressure | |||||

This serves as a reference. For any specific customizations, we warmly invite you to contact us to discuss your unique requirements.

INSTALLATION WAY

1. Cantilever crane

The cantilever crane utilizes a robust steel pipe column and I-beam main beam, offering a simplified structure, agile operation, and expansive working area.

2.Folding arm crane

Featuring a column, rotating arm, and lifting unit, the folding arm crane is engineered for precise positioning, coverage of multiple work zones, and efficient use of space.

3.Movable base cantilever crane

With full directional mobility, this crane delivers flexible operation, precise positioning, and an extensive operational range.

4.Truss crane

Designed with a lightweight steel structure, the truss crane is perfect for scenarios involving limited space, height constraints, or extensive travel requirements.

WORKING SCENARIO

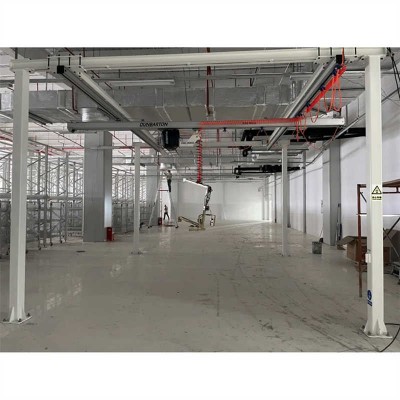

OUR FACTORY

FAQ

Q:Are you a manufacture or trading company?

A:We are the manufacturer, has more than ten years of production experience

Q: How long is your delivery time?

A: It is Usually 20 days after confirming the technical sheet and drawings.

Q: What is your price?

A: The price depends on your requirements for the equipment. Accordingto the model, the price is relatively different.

Q: What is the condition of your machine?

A: Brand new, can be customized.

Q:What is the guarantee of after-sales service?

A:Replacement parts within one year, lifelong technical guidance

Q:Mode of transportation?

A: You can choose sea, air, rail transportation (FOB, CIF, CFR, EXW, etc.)

Q:What problems can the Manipulator solve?

A:1.Perform dangerous or heavy operations in place of humans

2.Improve production efficiency and quality

3.Reduce labor costs and so on

Contact Supplier

LINKS : Dongqi Crane