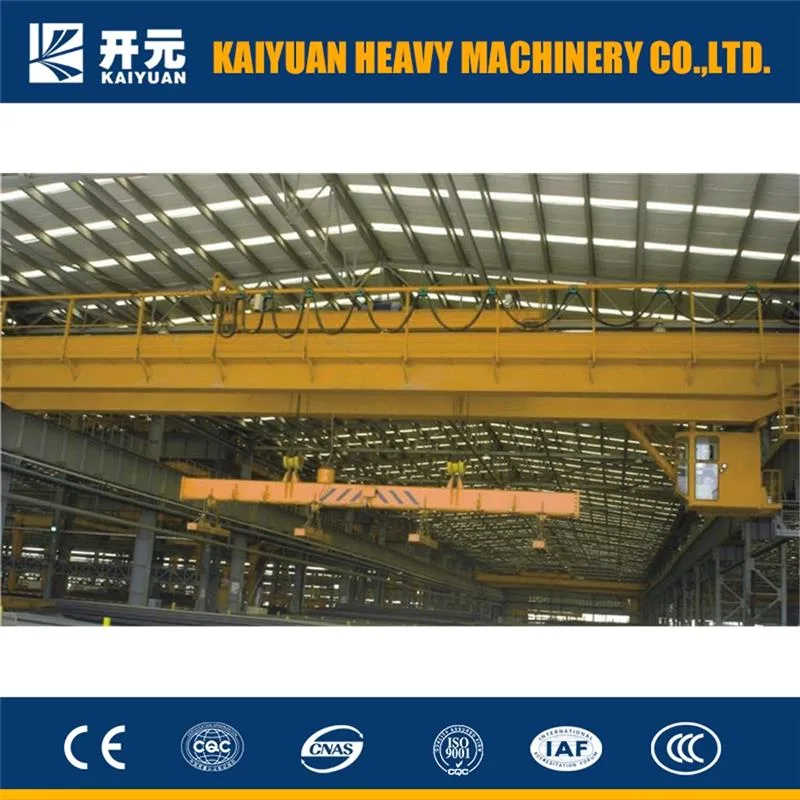

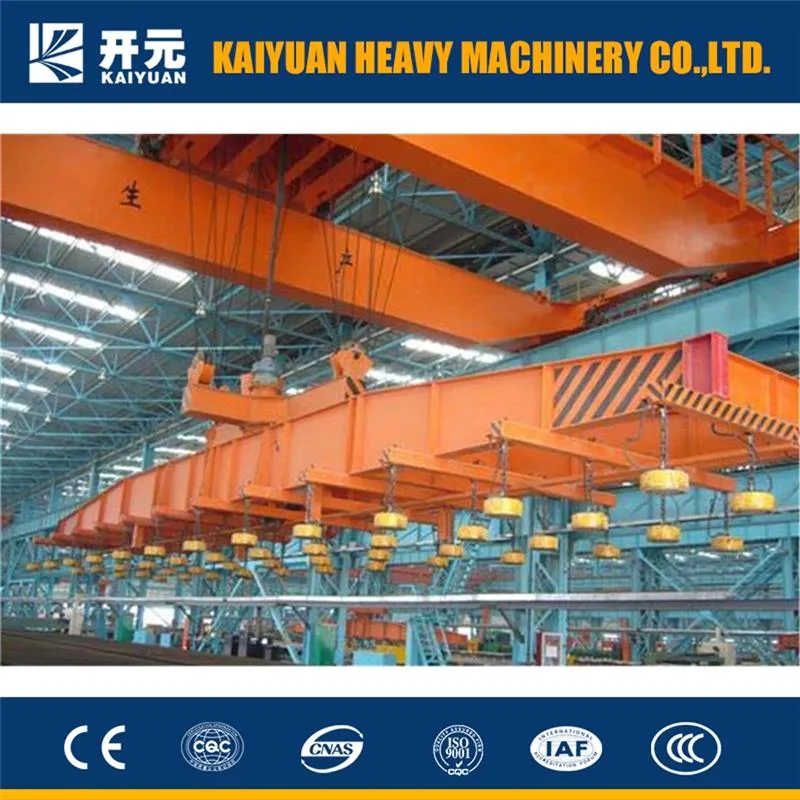

Lifting Type (20+20) Ton Electromagnetic Overhead Crane

$26800.00Product Description

PRODUCT DISPLAY

Together Lifting Type (20+20) Ton Electromagnetic Crane

The main part of the electromagnetic overhead crane is magnet and it carries steel items through electromagnetic principle. Making current, the electromagnet will catch up the steel material tightly and carry them to the pointed place; Breaking current, the electromagnet will disappear and then put the steel material down. The electromagnetic crane can produce powerful magnetic field force, it can carry dozens of tons of sheet iron, iron wire, iron nails, waste iron and other different kinds of iron material easily, all of them need not packaging and can be collected and carrying easily. It not only easy operating, but also simplify the work. It can also carry steel material and Roberts packaged in boxes. As long as there is current in magnet coil, the catching items would not down, the invisible magnetic force is much stronger than strong chains. If the current stooped, the steel talons on the crane will catch theses items tightly to avoid accident. The electromagnetic overhead crane cannot carry hot iron because the hot iron cannot be magnetized. The electromagnetic overhead crane can be used in wasted steel recycling sector and steel shop.

| Main Parameter | ||||||

| Lifting Capacity | t | 5.0-16.0 | 20/5-32/5 | (5+5)-(25+25) | ||

| Span | m | 10.5-31.5 or Designed | ||||

| Max. Lifting Height | m | 16 | 16.0-18.0 | 12.0-18.0 | ||

| Speed | Hoisting | Electromagnetic | m/min | 16.4-19.9 | 7.8-19.29 | 7.8-15.3 |

| Aux Hook | 19.5 | |||||

| Trolley Travelling | 39.5-45 | 42.4-45.9 | 84.7-91.9 | |||

| Crane Travelling | 101.4-116.8 | 86.6-115.0 | 86.6-112.5 | |||

| Motor | Hoisting | Electromagnetic | KW | 22-45 | 42-55 | 26-85 |

| Aux Hook | 13-15 | 34-10/110 | ||||

| Trolley Travelling | 1.5-3.7 | 5.5-6.3 | 2.5-6.3 | |||

| Crane Travelling | 2*5.5-2*11 | 2*8.5-2*15 | 2*4-2*18.5 | |||

| Weight | Trolley | t | 2.38-5.55 | 8.93-11.63 | 6-17.1 | |

| Total | 13.4-42.3 | 24.3-55.27 | 17.2-71.8 | |||

| Electro-magnetic Disk | Model | MW5-90L/165L | LMC-240A | |||

| Attracting Weight | t | 4.2-12.5 | ||||

| Self-weight | 0.8-3.2 | 7 | ||||

| Diameter | mm | 900-1650 | ||||

| Max. Wheel Load | KN | 74.5-213 | 115-335 | 108-483 | ||

| Working Group | A6 | A6 | A5-A6 | |||

| Steel Track Recommended | 38-43kg/m QU70 | 50kg/m QU70 | P18-P80 QU70-100 | |||

| Power Supply | 3P AC 380V 50Hz | |||||

WHY CHOOSE US

1. More than 10 years crane manufacture experience.

2. Unique International standard indoor warehouse for crane manufacture.

3. We have the senior crane design engineers, with professional design. And very expert crane mechanical and electrical installation engineer team.

4. Our crane sales team will help to supervise the crane whole production and seaport loading, we prefer to /confirm/i every small details.

5. We know how to shipment the crane in a very compact and reasonable way, save sea freight for our oversea crane client.

PACKAGE AND DELIVERY

Packaging Details: | packaging: 1. Electric parts are packed in iron box to reduce distortion in conveying; |

Delivery Day | Within 30 work days after receiving the deposit |

Contact Supplier

LINKS : Dongqi Crane