Maintenance of hydraulic lifting platform

Hydraulic lifting platform is a commonly used lifting equipment for moving objects in vertical space. It is generally hydraulically driven, also known as hydraulic lift. It can be divided into two types: fixed and mobile. In the process of use, hydraulic lifting must be done. Maintenance work of the platform.

Monthly maintenance of hydraulic lifting platform:

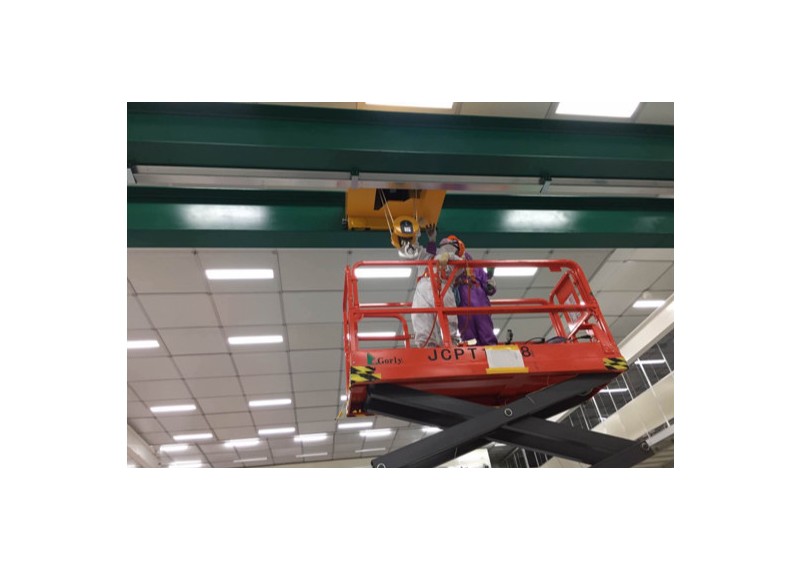

During maintenance of the hydraulic lifting platform, when personnel enter the interior of the lifting platform to work, the elevator must be hung to prevent the lifting platform from falling suddenly and causing casualties.

1. Check the lubrication and wear conditions of rollers, intermediate shafts and bearings; cylinder pins and bearings; boom hinge shafts and bearings;

2. Fill the above-mentioned parts with lubricating oil. Extend bearing life.

3. Check the hydraulic oil quality and oil level. The hydraulic oil level should be 40-50 mm higher than the bottom of the oil tank when the lifting platform is raised to the highest point. When the oil color of the hydraulic oil becomes dark, the oil is sticky, or there are foreign objects such as grit in the oil, the hydraulic oil should be replaced in time. The hydraulic system of the lifting platform uses 32# hydraulic oil.

Year-end maintenance of hydraulic lifting platform:

1. Check the hydraulic and pipeline connections. If the pipe is damaged, replace it immediately; tighten the pipe joint when the connection part is loose.

2. Remove and disassemble the lowering valve, blow the valve core with compressed air and reinstall it.

3. Drain all the hydraulic oil in the oil tank. Open the oil tank, take out the oil suction filter, clean it, put it back into the oil tank, and install it in the original position. The fuel tank is refilled with new oil.

Doing a good job in the maintenance of the lifting platform can effectively extend the service life of the equipment and reduce the incidence of equipment failure. Enterprises must pay attention to it.