Rmg Type Rail Mounted Container Double Beam Gantry Crane

$500000.00Rail-mounted container gantry cranes (RMG) is a specialized yard container handling machine. It can travel on rail by means of the yard power, and lift an stack containers in the yard area with the equipment of the 20' or 40' telescopic spreader (or twin-lift spreader if needed). The RMG has the advantage of being driven by electrical power, clean, bigger lifting capacity, an high gantry traveling speed with cargo. The RMG consists of lifting mechanism, trolley traversing mechanism, gantry mechanism and sway-dampening mechanism.

The lifting, gantry and trolley mechanisms are mostly equipped with AC frequency conversion control system. Normally the lifting mechanism is of the single drum type. It can also be designed to be double drum type if needed. Our corporation can design and manufacture according to demands of user.

Application: container terminals, open storage yards and along the railway lines to load or unload container

Technical Introduction:

1. The electrical equipment is accommodated in robust steel plate control cubicles.

2. All movement can be switched off by actuating the emergency-off switch at the control station via a main contactor.

3. The entire equipment is easy to install and dismantle due to the use of threaded bolts and top-hat rails. Cable inlet from the cable gland.

4. Power supply cable and control cable along the girder

5. A protective earth conductor is fitted as standard, a crane switch is provided.

6. Travel end switches, long and cross travel limited by means of preliminary and final limited switches and overload protection:

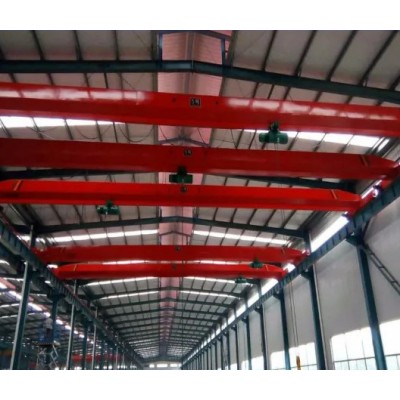

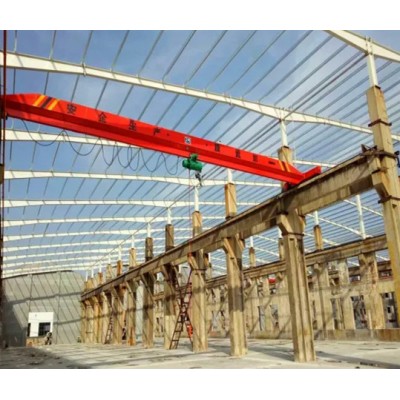

Design Structure

It runs on a runway at the floor level. The bridge is supported by a pair of rigid steel legs which are carried by a pair of end trucks along the floor level runway.

Double Girder Gantry Crane Technical data:

Capacity (t) | 10 | 16 | 20/10 | 32/10 | 36/16 | 50/10 | ||||||||||||||||

Span (m) | 18 | 22 | 26 | 30 | 35 | 18 | 22 | 30 | 18 | 22 | 26 | 30 | 35 | 22 | 26 | 22 | 26 | 30 | 35 | 35 | ||

Lifting height (m) | Main | 11.5 | 10.5 | 12 | 10.5 | 11.5 | 11.5 | 12 | ||||||||||||||

Aux. | 11 | 12 | 12 | 13 | ||||||||||||||||||

Working class | A5 | |||||||||||||||||||||

Speed (m/min) | Lift | Main | 8.5 | 7.9 | 7.2 | 7.5 | 7.8 | 6 | ||||||||||||||

Aux. | 10.4 | 10.4 | 10.5 | 10.4 | ||||||||||||||||||

Travel | Handcart | 43.8 | 44.5 | 44.5 | 41.9 | 41.9 | 38.13 | |||||||||||||||

Crane | 37.6 | 40 | 38 | 36 | 38 | 36 | 40 | 40 | 38 | 38 | ||||||||||||

Power supply | 3-phase 380V 50HZ | |||||||||||||||||||||

Mechanical feature

Double welding box girder, DIN/FEM standard deflection

Steel tube legs

Material Fe37 or Fe52

Whole length CNC cutting for complete web plate, high deflection accuracy

High quality automatic welding and NDT inspection

Shot-blasting Sa2.5 for complete girder after welding, stress release

Epoxy zinc rich high quality painting, 2x2 with 140μm

10.9 class High tension bolts mounting between girder and legs, life time safety connection

Vertical gear motor driving, more safety and smaller space

High protection class IP55, F class, 40% ED

End carriage equipped with anti-friction bearings, cellular buffers, and derailment protectors

Contact Supplier

LINKS : Dongqi Crane