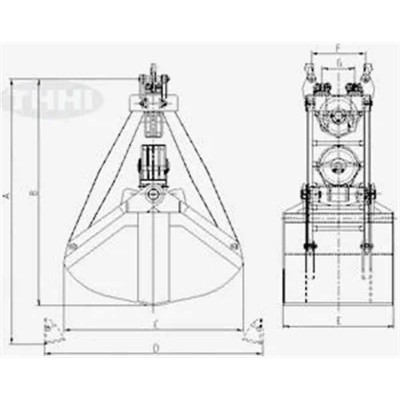

12cbm Wireless Remote Conteol Clamshell Grab

$25000.00Product Description

Wireless Remote Control Clamshell Grab

Certification: BV,CCS

Place of Origin: China

Minimum Order: 1 Unit

Price: 15000~50000 USD

Payment Terms: T/T

Supply Ability: 300 Units

Delivery Time: 50 Days

Packaging Details: Nude

Material: Q345

Volume: 2m3

Power: 22kw

Color: As required

6-8-10-12CBM Wireless Remote Control Clamshell Grab

This novel bulk radio wireless remote control grab can automatically close on the material pile and open in the air without any additional energy. It has both the adv This novel bulk grab can automatically close on the material pile and open in the air without any additional energy. It has both the advantages of simple structure and reliable operation of the rope type grab and high productivity of the powered grab. As a result of the combination of mechanical structure and electronic device, this new invention enjoys high reputation from our customers. Its birth terminates the low efficiency of single rope grab in hoisting.antages of simple structure and reliable operation of the rope type grab and high productivity of the powered grab. As a result of the combination of mechanical structure and electronic device, this new invention enjoys high reputation from our customers. Its birth terminates the low efficiency of single rope grab in hoisting.

Working Principle of Remote Control Grab

Grab Closure: when the grab is open, the middle bearing beam contacts the upper bearing beam and is completely separated from the lower bearing beam. At this time, the electromagnetic reversing valve is closed. Because the piston rod of the oil cylinder is fixedly connected with the middle bearing beam and the cylinder barrel is fixedly connected with the lower bearing beam, the piston rod of the oil cylinder is fully extended at this time. When the cargo is to be grabbed, the crane sling will be lowered. Because the piston of the oil cylinder can conduct in one way, the piston rod of the oil cylinder can shrink and the middle bearing beam will be lowered accordingly. When the piston rod of the oil cylinder is fully retracted, the middle bearing beam also falls completely. Then the crane sling rises, and the middle bearing beam rises with it. As the solenoid valve of the oil cylinder is normally closed, the rod cavity of the oil cylinder is locked, and the oil cylinder is closed and locked. Under the function of the pulley block, the middle bearing beam rises, driving the lower bearing beam upward and driving the jaw flap to close.

Grab Opening: when the grab needs to be opened, just press the switch of the remote transmitter, open the electromagnetic reversing valve of the oil cylinder, so that the oil cylinder has a rod cavity for unloading. The cylinder piston rod is pulled out under the action of the middle bearing beam and the lower bearing beam respectively, the middle bearing beam and the lower bearing beam are separated, and the grab is opened.

Wireless Remote Control Clamshell Grab - Jim Sun2

Hydraulic schematic diagram of remote control grab

A. hoist the open grab and extend the cylinder piston rod.

Hydraulic schematic diagram (a)

B. after the open grab is placed on the goods with the crane, loosen the steel wire rope, the piston rod of the oil cylinder will be lowered by the gravity of the middle bearing beam, and the piston will move down. Part of the hydraulic oil in the lower space of the oil cylinder will enter the upper part of the oil cylinder through the one-way valve on the piston, and the excess oil will be pressed back to the oil tank

Hydraulic schematic diagram (b)

C. when the piston moves down to the bottom of the oil cylinder, the hydraulic oil in the lower part of the oil cylinder can only flow back to the oil tank through the hose, while the hydraulic oil in the upper part of the oil cylinder is connected with the solenoid valve and the reversing cartridge valve through the hose, and the solenoid valve is still in the locked position.

Hydraulic schematic diagram (c)

Hydraulic schematic diagram (d)

D. lift the steel wire rope to drive the middle beam to lift the lower bearing beam. The lifting force of the lifting equipment is transmitted to the upper bearing beam and piston through the steel wire rope. Because the hydraulic oil in the upper part of the oil cylinder is locked, the oil can not flow out and generate oil pressure, which makes the oil cylinder and the lower bearing beam of the grab move upward together, and the bucket body is lifted together with the steel wire rope. The grab grabs the material and lifts it.

Hydraulic schematic diagram (E)

E. After the material is lifted by the grab, it is moved to the destination with the crane. The operator presses the grab remote control button, and the center beam with the piston rod of the hydraulic cylinder holds the upper bearing beam of the grab under the action of the crane. The lower bearing beam moves downward due to the release of the self weight and the pressure of the upper cavity of the hydraulic cylinder, and the grab opens to unload the material.

The pressure oil in the upper cavity of the hydraulic cylinder reaches the electromagnetic reversing valve and the reversing cartridge valve at the same time. As the electromagnetic reversing valve is electrified, the pressure oil acting on the reversing cartridge valve core is released, the reversing cartridge valve core moves up, the reversing cartridge valve is opened, and the pressure oil in the oil cylinder flows back to the grab oil tank through the hose and reversing cartridge valve.

At the same time of oil return in the upper cavity of the oil cylinder, a vacuum is formed in the lower cavity of the oil cylinder. Due to the effect of air pressure and hydraulic oil flowing into the oil tank, the oil in the oil tank flows into the one-way valve on the oil suction pipeline through the oil suction filtration device, and finally reaches the lower cavity of the oil cylinder. The piston rod extends to complete the opening action of the grab.

Contact Supplier

LINKS : Dongqi Crane