Electric Chain Hoist

$500.00OVERVIEW

Electric chain hoist is a light and small lifitng equipment. Consisted of motor, transmission mechanism and chain wheel. Beatifull outlooking, Solid Durable. Inside gears there are hot-quenched then increase the wear resistance of the gear and toughness. Adopt international advanced technology, fine workmanship, gear wheel tight fit.

Electric Chain Hoist Supply Options

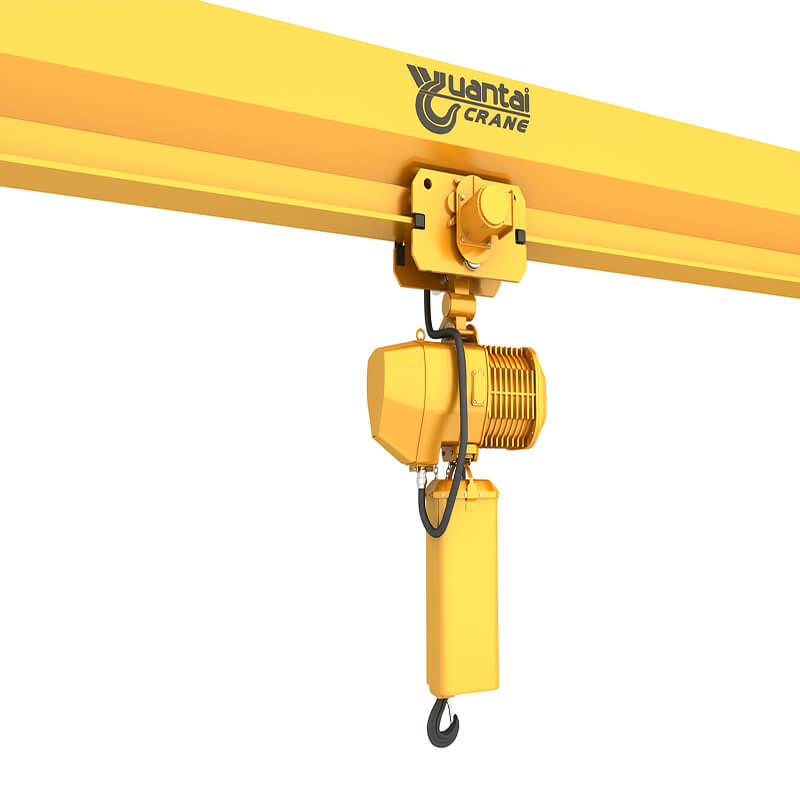

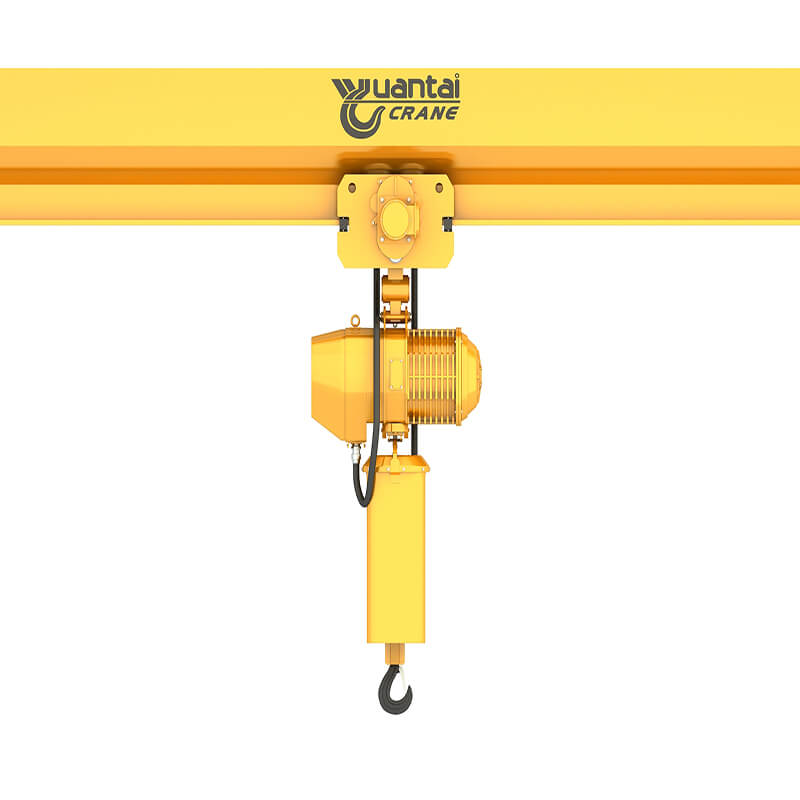

Hook type electric chain hoist

Electric chain hoist with manual trolley

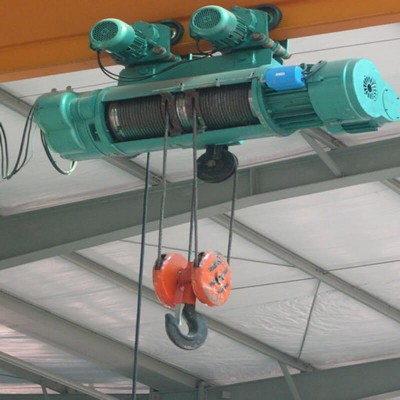

Electric chain hosit with electric trolley

Low headroom electric chain hoist

FEATURES

In General

Compact structure, small size, light body weight

Reliable, easy operation, wide using scope.

Usage & Application

Widely used in factory, storage, wind-power station, logistics, port and construction field.

Usd for lifting or loading. Or lifting heavy objects for working or repairation.

It can be controlled by handle on ground or wire(no-wire) remote controll.

It can be suspended and fixed for using, or matched with monorail electric trolley(as following pictures.)

Structure Features

The body chooses to use high strength tensile shell or die casting aluminum case, extrusion molding process thin-walled precision manufacturing, small size, low weight, high strength.

Seperate speed-adjusting system, seal the level 2 coaxial transmission speed gear mechanism with long-service oil bath lubrication system.

The electric hoist powder metallurgy clutch is used for overload protection device. The brake disc adopts dc magnetic field, braking torque, stable and rapid, the noise is small.

Lifting motor

Using high performance lifting motor which can last to work 30 minutes with full loading, and has Grade B insulation.

Lifting chain

The chain of the low carbon steel alloy makes the chain more toughness, strong and wear-resisting, ensuring the safety during work.

Lifting chain hardened surface can prevent the damage of the core materials and products to soften, thus make lifting chain keep for a long time high performance.

The chain can be also extended according to the request of customers' order, and allows you to use more conveniently.

The chain is equipped with chain bag which makes the electric hoist looks clean, tidy and beautiful. the chain bag contains antirust oil, so the chain is not easy to rust , so as to extend the service life of the electric hoist.

Double brake system

Two sets of brake systems, not only reduce the brake failure possibility, but also increase its safety and benefit for heat radiation.

Electromagnetic brake. The new brake system responds quickly and provides positive braking force. The use of non-asbestos brake linings greatly extends the maintenance cycle. The brake system was tested more than 22,500 times.

Mechanical brake. Very reliable mechanical braking and electromagnetic brake are mutual coordination, can stop truning machine at any time.

Variable speed tooth

The standard chain electric hoist mainly use the reliable helical gear, it can prolong service lifting through reducing the meshing impact and vibration.

Special design of gear enhance the durability of gear, And gear is made of alloy steel, through professional fine heat treatment obtain the biggest strength.

Control handle with low voltage

The standard low-voltage on chain hoist handle is 24v-36v. Low voltage can effectively protect the operator to prevent a shock damage.(24V-36V is compulsive National standard.)

Contact Supplier

LINKS : Dongqi Crane