Explosion proof single beam crane - direct sales from Chinese factory origin

$5000.00Explosion proof single beam cranes are mainly used in industrial fields and occasions that require explosion-proof performance, including but not limited to the following main industries:

Petrochemical industry: In refineries, chemical plants and other places, explosion-proof single beam cranes are commonly used in crude oil processing, chemical production equipment maintenance, dangerous goods transportation and other processes.

Pharmaceutical industry: In pharmaceutical factories and enterprises, explosion-proof single beam cranes can be used for handling and loading and unloading flammable and explosive chemical raw materials or finished drugs.

Paint and coating industry: In industries such as automobile manufacturing and shipbuilding, explosion-proof single beam cranes can be used to transport flammable materials such as paint and solvents, and operate in explosion-proof areas.

In the aerospace industry, explosion-proof single beam cranes can be used for handling and installing lightweight and flammable aviation components during aerospace manufacturing and maintenance processes.

In addition, explosion-proof single beam cranes are also suitable for industries such as steel metallurgy, hydropower, coal, etc., all of which have strict requirements for the explosion-proof performance of equipment. Through explosion-proof design and explosion-proof control system, explosion-proof single beam cranes can ensure safe and reliable operation of equipment in potential fire or explosion hazardous environments, reducing work safety risks.

It should be noted that the use of explosion-proof single beam cranes must strictly comply with relevant regulations and precautions to ensure the safety and stability of the equipment. Before use, safety checks must be conducted, and operators must undergo professional training to understand operating procedures and precautions. Overloading is strictly prohibited, and maintenance and upkeep must be carried out in accordance with regulations.

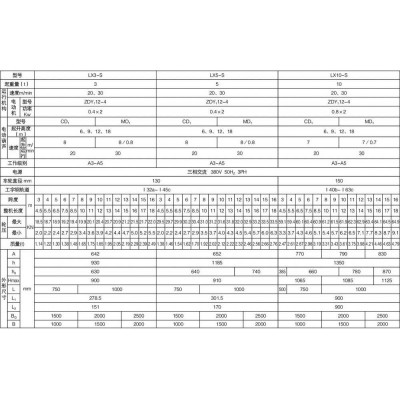

The parameter range of explosion-proof single beam cranes varies depending on specific models and manufacturers. The following are some common parameter ranges:

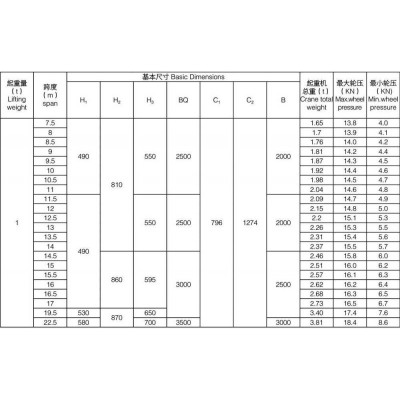

Lifting capacity: usually between 1-16 tons, depending on the design and application requirements of the crane.

Span: typically between 7.5 and 22.5 meters, some models may have a larger span range to meet the needs of different workplaces.

Work level: A3~A4 are common work levels, but there may also be other levels depending on the design standards and working environment of the crane.

Working environment: Usually able to operate normally within the temperature range of -25~+40 ℃, some special models of explosion-proof single beam cranes may have a wider working temperature range.

In addition, the specific parameters of explosion-proof single beam cranes may also include explosion-proof level (such as ExdIIBT4 and ExdIICT4), motor type (general motor or KDJ motor), external dimensions of the crane, and cargo box dimensions. These parameters will be customized according to the actual application scenarios and user needs of the crane.

Contact Supplier

LINKS : Dongqi Crane