5 ton European single beam crane - Direct Sales From Chinese Factory Origin

$15000.00The European single beam crane has multiple significant characteristics. Firstly, its lightweight, compact structure, and low energy consumption are mainly attributed to its unique design philosophy. Secondly, its small size, light weight, and low wheel pressure make the European crane have the minimum limit distance from the hook to the wall and the lowest clearance height when working close to the front, thereby increasing the effective working space of the existing factory building. In addition, due to its light weight and small wheel pressure, the space design of the new factory can be more compact and fully functional, thereby saving initial construction investment and long-term maintenance costs.

In terms of operation, European single beam cranes offer two forms: ground operation and aerial operation. Ground operations include wire handle operation and remote control handle operation, while aerial operations are completed through the driver's cab. The driver's cab of the electric hoist single beam crane has two options: open and closed, and can be installed on the left or right side according to the actual situation. The entrance direction also has two options: side and end to meet the needs of different users.

In terms of application, European single beam cranes are widely used in indoor and outdoor warehouses, factories, docks, open-air storage yards, as well as in mechanical manufacturing workshops, metallurgical workshops, petroleum, petrochemical, port, railway, civil aviation, power plants, papermaking, building materials, electronics and other industries, warehouses, material yards and other occasions. It is suitable for cargo lifting and handling operations in production, logistics, warehousing and other fields, including mechanical processing, automotive production, power equipment manufacturing, petroleum, chemical and shipbuilding industries.

However, it should be noted that European single beam cranes are prohibited from being used in flammable, explosive, or corrosive media environments. In addition, although European single beam cranes have many advantages, relevant safety regulations and operating procedures still need to be followed during use to ensure the safety of personnel and equipment.

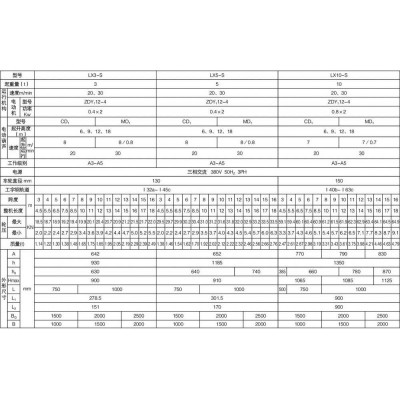

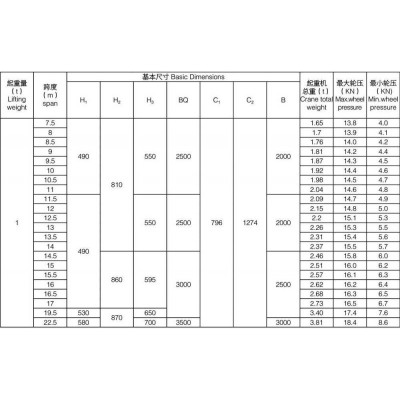

The parameter range of European single beam cranes varies depending on their different models and uses. Here are some common parameter ranges:

Lifting capacity: The lifting capacity is usually expressed in tons, ranging from a few tons to several tens of tons. For example, the lifting capacity of LD type European single beam crane is 1-10 tons, while the lifting capacity of LX type European single beam crane is 5-50 tons. In addition, some European style single beam bridge cranes can even reach a lifting capacity range of 1-32 tons.

Span: The span of a European single beam crane refers to the effective span of the crane beam, which is the maximum range of the crane beam's transverse span. Its span range usually ranges from 7 to 30 meters, depending on the model and working environment of the crane.

Lifting height: Lifting height refers to the maximum height that a crane can vertically lift goods. This parameter determines the operating range of the crane in the vertical direction. The lifting height of European single beam cranes generally has multiple specifications, such as 4 meters, 6 meters, 8 meters, 10 meters, etc., and can also reach 6 to 30 meters. Users can choose the appropriate lifting height according to their actual needs.

Work level: The work level of European single beam cranes is determined based on their frequency of use and working time. Common job levels include M3~M6, A1~A8, and other levels, and different levels of cranes are suitable for different working environments and intensities.

Contact Supplier

LINKS : Dongqi Crane