The cooling wall of blast furnace is repaired by Chenghua hoist hoist

The cooling wall is the cooling equipment inside the blast furnace, placed between the furnace shell and the furnace lining, and the main material is cast iron, cast steel or copper. The cooling wall is mainly used in the tuyere and the following areas to cool the lining of the blast furnace. In the process of blast furnace production, the blast furnace lining and cooling equipment are subjected to complex chemical erosion, mechanical friction, thermal stress and high temperature, the cooling components in the lower part of the blast furnace will be damaged, and the cooling equipment must be overhauled to a certain extent to ensure the safety of blast furnace production. In order to extend the service life of the blast furnace cooling wall and reduce the occurrence of faults, the factory will regularly overhaul the cooling wall to extend the service life of the blast furnace cooling wall as far as possible.

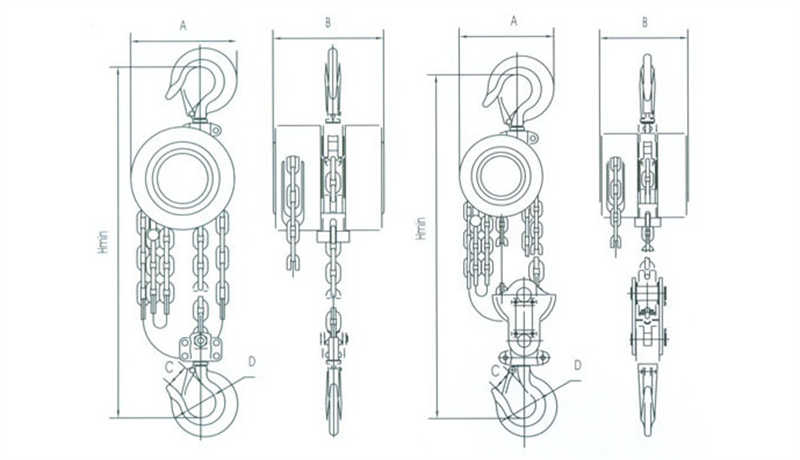

Blast furnace cooling wall is the key equipment in blast furnace production and the necessary condition to ensure the safety of blast furnace production. Blast furnace cooling tower maintenance workload is larger, the use of more equipment, such as Chenghua hoist, hoist, pulley and so on. Special trays for the installation of cooling walls are made in the blast furnace to ensure that the special passage for the lifting of cooling walls is unimpeded. A hoist and a fixed pulley are set on the top platform of the furnace, and the cooling walls are hoisted by a hand-pulled hoist for the maintenance of the furnace top can save time, reduce the maintenance cost and improve the work efficiency. During the maintenance of the blast furnace cooling wall, the hand hoist can not only be used for lifting operations, but also for equipment fastening, traction and other operations. During the operation, the hand hoist is hung on the hook hook at the fixed point, the lower hook hook hook hangs the suspended weight, the operator pulls the hand chain, the suspended weight will be slowly lifted, and the heavy object will be lifted to the designated position, but the lifting hook is unloaded. In this way, the labor intensity of operators is reduced, the operation is flexible, the safety factor is high, and the progress of cooling wall maintenance is accelerated.

In order to ensure that the operator can safely and smoothly complete the cooling wall maintenance operation, what matters should be paid attention to during the maintenance of the blast furnace cooling wall?

(1) A strict system of equipment use, maintenance and overhaul should be established. Equipment should be repaired as scheduled without delay. The mechanical and electrical technicians of the equipment management department shall be responsible for daily maintenance work.

(2) The maintenance site should set up a unified headquarters, and clarify the safety responsibilities of each unit. Units participating in the maintenance work shall, under the unified guidance of the maintenance headquarters, work according to the divided operation area and scope.

(3) Before the overhaul, there should be special personnel to confirm the key parts and safety facilities such as electricity, gas, steam, oxygen, nitrogen, and handle the relevant overhaul and fire approval procedures.

(4) In the maintenance, the safety device should be removed as planned, and there are safety protection measures. After maintenance, the safety device should be restored in time. The change of safety protection device shall be approved by the safety department and shall be recorded and filed.

(5) The assembly table and assembly operation used in major and middle repair shall meet the requirements of major and middle repair headquarters and shall not impede traffic. Assembling operation should have special command and supervision.

(6) Vehicles running on the construction site should be directed by special personnel, and one-way lanes should be set up as far as possible. In large and medium repair construction areas, the train speed should not exceed 5km/h, and warning signs and signals should be set up.

(7) Equipment maintenance and replacement, must strictly implement the safety system and professional safety technical operating rules. Maintenance personnel should be familiar with relevant drawings, data and operation technology. Before maintenance, safety education should be carried out for maintenance personnel, the site working environment and precautions should be introduced, and the construction site safety disclosure should be made.