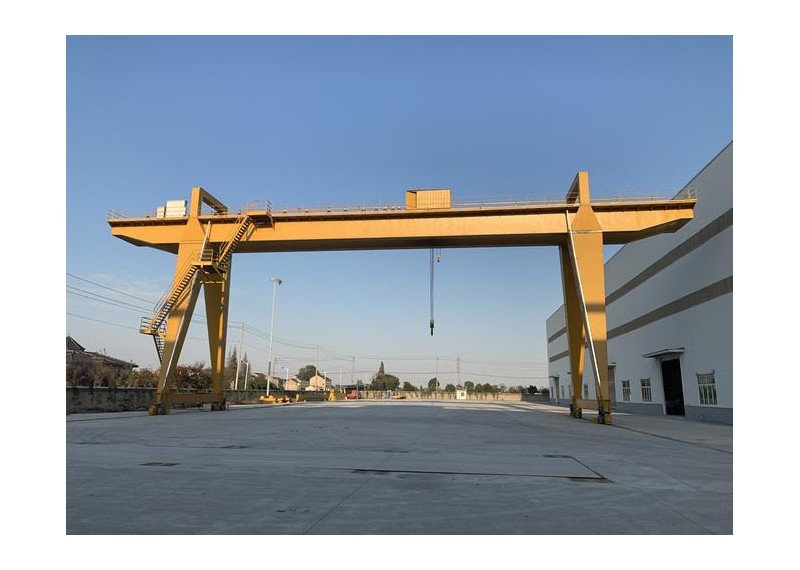

10 ton gantry crane foundation design for track plate factory

Design Overview

In order to meet the production needs of the track plate factory, a 10 ton gantry crane foundation design for track plate factory gantry crane is specially designed. The gantry crane will be used to hoist and transport track plates. Its foundation design must ensure stability and safety, and comply with relevant engineering specifications and geological conditions. The following is a detailed description of the foundation design of the gantry crane.

Design Basis

Foundation engineering theory: based on the basic principles of foundation treatment, foundation selection and structural design.

Geological exploration data: including key data such as foundation bearing capacity and soil properties.

Data provided by the gantry crane manufacturer: including parameters such as the size, weight, and maximum hoisting capacity of the gantry crane.

National relevant design specifications: such as "Code for Design of Building Foundations" (GB50007-2002), "Code for Design of Concrete Structures" (GB50010-2002), etc.

Design parameters

Gantry crane specifications: 10T, the span is determined according to the actual site, and the floor height is set to a reasonable height according to the hoisting requirements.

Foundation bearing capacity: According to geological exploration data, the characteristic value of foundation bearing capacity is not less than XXXKPa.

Foundation form: reinforced concrete strip foundation is adopted to ensure stability and durability.

Concrete strength grade: C30, meeting the structural design requirements.

Steel bar configuration: According to the force analysis and structural requirements, the steel bars are reasonably configured to improve the bearing capacity and crack resistance of the foundation.

Foundation design

Foundation bottom surface design:

According to the wheel pressure distribution of the gantry crane and the bearing capacity of the foundation, the size and shape of the foundation bottom surface are designed. Ensure that the bottom surface is evenly stressed to avoid local damage.

Steel bar configuration design:

A certain number of steel bars are configured on the bottom surface to improve the compressive strength of the foundation.

Steel mesh is configured on the top surface, which together with the stirrups constitutes an overall force system to improve the crack resistance and bearing capacity of the foundation.

Others are configured according to the structural requirements to ensure the stability of the steel cage.

Expansion joint setting:

In order to cope with the expansion and contraction deformation caused by temperature changes, a 20mm wide expansion joint is set every 20m.

Foundation position determination:

The foundation position is determined according to the position of the beam pedestal to ensure that the running track of the gantry crane matches the production line.

Foundation verification

Foundation bearing capacity verification: According to the maximum wheel pressure of the gantry crane and the characteristic value of the foundation bearing capacity, the foundation bearing capacity is verified. Ensure that the foundation bearing capacity meets the design requirements.

Foundation deformation verification: According to the foundation compression modulus and load distribution, the deformation of the foundation is calculated. Ensure that the foundation deformation is within the allowable range to avoid adverse effects on the operation of the gantry crane.

Foundation internal force calculation

Calculation of bending reinforcement of the foundation positive section: According to the bending moment and shear force on the foundation, calculate the required number and diameter of steel bars. Ensure that the configuration of steel bars meets the structural design requirements.

Calculation of shear reinforcement of the foundation inclined section: Considering the shear force on the foundation, calculate the shear bearing capacity of the inclined section. Ensure the safety and stability of the inclined section.

Construction precautions

Foundation construction: Carry out foundation construction according to the design drawings to ensure that the foundation size, shape and steel bar configuration meet the requirements.

Concrete pouring: Use qualified concrete materials and pour and vibrate according to construction specifications. Ensure the quality and density of concrete.

Maintenance and testing: After the concrete is poured, it is fully maintained. At the same time, the foundation is inspected and accepted to ensure that it meets the design requirements.

Conclusion

This design designs the foundation of a 10T gantry crane based on the production needs and geological conditions of the track plate factory. Through detailed design calculations and explanations of construction precautions, the safety and stability of the foundation design are ensured. This design can provide strong support for the production of the track plate factory and meet the needs of lifting and transportation.

(Note: The specific values in the above design, such as the characteristic value of the foundation bearing capacity, the concrete strength grade, etc., need to be specifically calculated and determined according to the actual situation. At the same time, other factors such as geological conditions and climatic conditions need to be considered in the design process.)

Calculation Table of Foundation Reaction Force

Calculation Table of Foundation Reaction Force Calculation Table for Basic Bending Distance

Calculation Table for Basic Bending Distance

10 ton gantry crane foundation design for track plate factory