What to do if the wire rope electric hoist rope guide is damaged

Why is the rope guide of the electric wire rope hoist easy to be damaged? The rope guide is a powerful accessory that can prevent the wire rope from being confused during use. When it comes to the rope guide of a wire rope electric hoist, many people know that it is a vulnerable part. Do you know why? Of course, this has nothing to do with its quality. When fixing the rope guide, the lateral force is large and it is easy to break. The wire rope electric hoist accident is mainly caused indirectly by the failure of the rope guide. In daily inspections, it is often found that there is no rope guide or the rope guide is loose or broken, which cannot play the role of rope braiding.

The breaking of the rope guide is a common fault in the use of electric hoists, which will cause the upper and lower limits of the electric hoist to fail. Since the upper and lower limits are triggered by the metal rods on the rope guide to drive the fire switch, the failure of the upper and lower limits will cause the hook to rise and break the wire rope, resulting in a fall accident. In addition to incorrect installation of the rope guide, illegal operations, tilt pull and tilt pull lift are also the direct causes of this phenomenon. In daily inspection work, it is often found that many operators have poor safety awareness. In the process of using cranes, they blindly pursued speed and convenient drawings without proper installation and operation procedures. Why is it not easy to replace the vulnerable parts of the wire rope electric hoist?

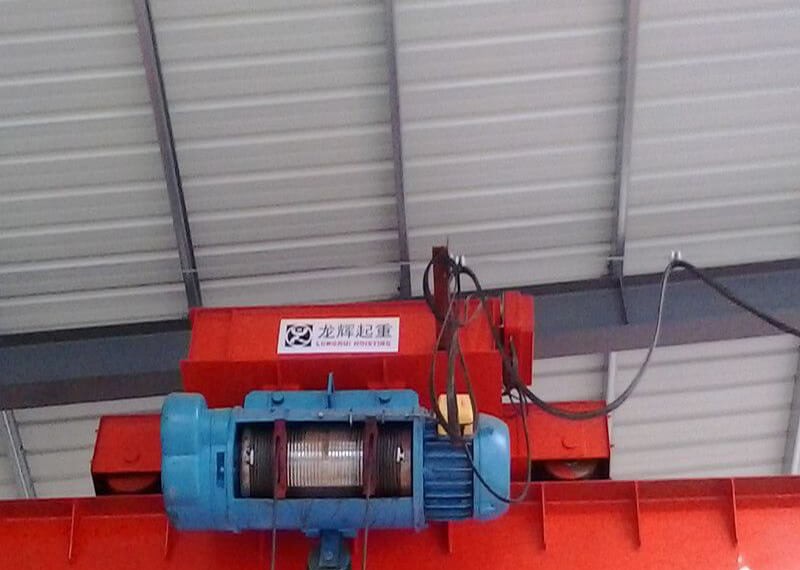

The rope guide of the electric wire rope hoist is the vulnerable part of the electric wire rope hoist. It is said that it is prone to problems during use and needs to be replaced frequently. However, even so, the position of the rope guide of the electric wire rope hoist is not easy to change. The basic function of the wire rope electric hoist rope guide is to prevent the wire rope electric hoist from being entangled on the rope irregularly. The rope guide itself cannot be rotated. When the drum rotates, it is wound by the steel wire rope and moved in the axial direction under the drive of the spiral groove. The wound wire rope can be accurately introduced and pulled into the spiral groove of the drum at any time, and the wire rope can be released from the gap of the rope guide. The nut of the rope guide is cut into 5 pieces, which are connected by the connected steel belt and the rope guide plate, and the steel wire rope extends from the long groove of the rope guide plate.

The rope guide nut engages with the rope groove of the drum, and the rotation of the drum drives the rope nut to move laterally to ensure that the wire rope does not move disorderly in the rope groove of the drum. The rope guide plate moves horizontally to both ends of the drum. When reaching the limit position, the limit rod installed on the cylinder is driven to move together. When the limit position is reached, the comfort switch installed on the main motor will trigger to act as the limit position. The rope guide is usually small, made of alloy steel, and needs to function as a rope arrangement without affecting the orderly arrangement of the wire rope on the drum. There is no better tool that can be replaced and have the same effect, so the rope guide is not easy to replace.