Harm of overloading of wire rope electric hoist

When the electric wire rope hoist is overloaded, the lower hook and the wire rope will be damaged first. Long-term overload operation will cause cracks in the wire rope and small hooks, which will directly crack for a long time, resulting in safety accidents.

Accidents of electric hoist gearboxes fall from time to time. According to the cause of the accident, analyze the unsafe conditions of objects and unsafe behaviors of people to avoid similar accidents.

Overloading may cause the center of gravity to be unstable, causing suspended objects to collide with surrounding objects. The hanging objects and surrounding objects will be damaged to varying degrees. Improve the design to eliminate the hidden dangers of the equipment from the source, so that the wire rope cannot be separated from the drum and then wound into the gap between the drum and the reducer, such as adding rope blocking equipment at the end of the drum or reducing the end of the shell and the drum.

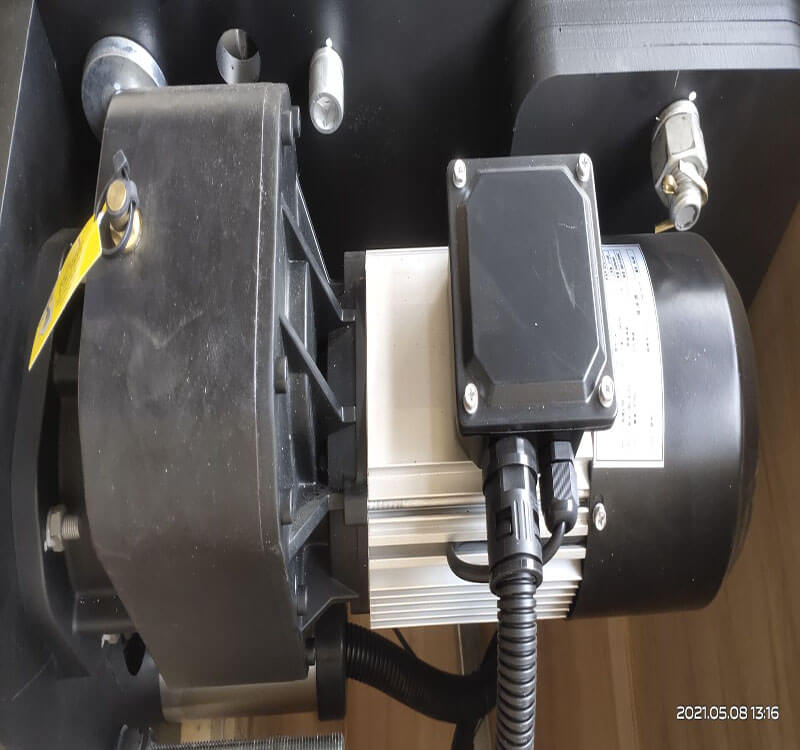

Electric hoist gearbox dropped overloading for a long time will cause the motor to heat up quickly and radiate slowly, which will reduce the service life of the motor and even burn the motor. The main reason for the falling accident is the cracking of the spiral cylinder cap surface of the reduction gear box. Except that the gap between the drum and the reduction gearbox involves the extrusion of the wire rope, it will cause the reduction gearbox screw bearing surface to crack; the deformation of the housing caused by the hook punching will also cause the reduction gearbox screw bearing cover surface to crack. Therefore, the tensile strength of the gearbox should be improved, such as using cast steel instead of raw materials, adding transition fillets, adding wall thickness or improving the design.