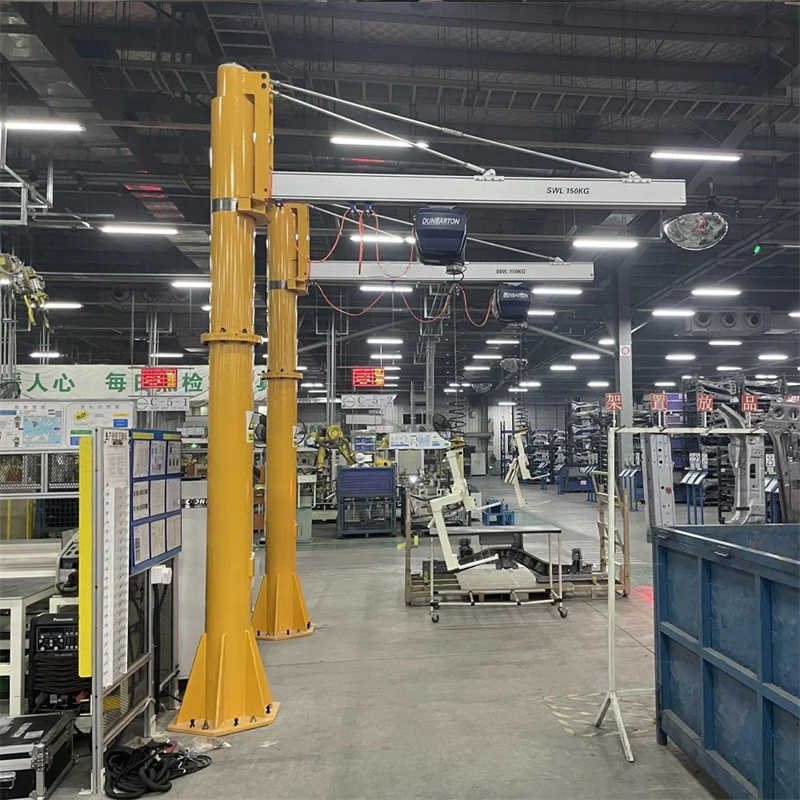

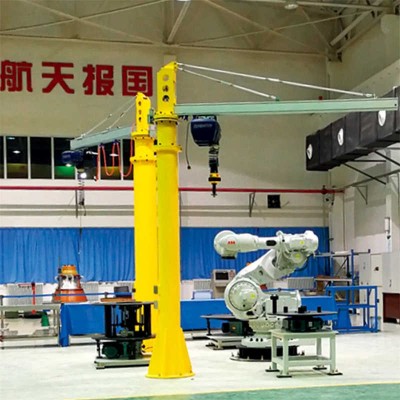

200kg Cantilever Crane Intelligent Elevator Intelligent Hoist

$6000.00Product Description

GENERAL INTRODUCTION

Jib Crane is a kind of manipulator equipment with cable. It realizes the lifting function by connecting the auxiliary lifting equipment installed on the mechanical arm with the fixture by soft cable.

The equipment is used with various non-standard fixtures to realize workpiece handling, palletizing, loading and unloading. It reduces operator fatigue, maximizes productivity, and ensures worker safety. It has a wide range of applications, especially for modern production lines.

CORE TECHNOLOGY

Jib Crane consists of three parts: column and cantilever arm, auxiliary lifting equipment and non-standard fixture.Auxiliary lifting equipment includes Electric hoist, intelligent auxiliary elevator and pneumatic balance hoist:

1.Electric hoist uses a two-speed control mode; It has low cost, simple installation and operation, low maintenance cost, and is suitable for factory warehouses and other places.

2.Intelligent auxiliary elevator is composed of servo drive, servo motor, reducer, etc., and is controlled by a microprocessor, which can get the working direction of the power from the operator and generate the power toward upward and downward.Within the rated range, the workpiece can be moved at any variable speed to achieve efficient handling. It has easy operation, high precision, intelligent, controllable speed and safe and reliable.

3.Pneumatic balance hoist has the whole suspension function in the free stroke, which can realize the accurate positioning of the workpiece load shifting assembly and easy operation.

PARTS AND STRUCTURE

1.Column

2.Cantilever arm

3.Auxiliary lifting hoist

4.Handle

5.Tooling Structure

MODELS FOR REFERENCE

1.Electric hois

| NAME | BMS125 | BMS250 | BMS500 | BMS1000 | BMS2000 |

| Maximum load(Kg) | 125 | 250 | 500 | 1000 | 2000 |

| Lifting speed (m/ min) | 8/2 | 8/2 | 8/2 | 4/1 | 4/1 |

| Motor power(Kw) | 0.4/0.1 | 0.4/0.1 | 0.4/0.1 | 0.75/0.2 | 1.5/0.37 |

| Lifting Medium | Chain | ||||

| Power supply | 220-460V | ||||

2.Intelligent auxiliary elevator

| NAME | IAD-H80 | IAD-H200 | IAD-H300 | IAD-H600 |

| Maximum load(Kg) | 80 | 200 | 300 | 600 |

| Handle-Lifting speed-unloaded (m/ min) | 40 | 30 | 15 | 7.5 |

| Float-Lifting-speed-unloaded (m/ min) | 36 | 27 | 13.5 | 6.75 |

| Maximum stroke (m) | 3.5 | 3.5 | 3.5 | 1.7 |

| Lifting Medium | Wire rope | |||

| Power supply | 220V±10% 50HZ | |||

3.Pneumatic balance hoist

| NAME | BW005060 | BW015080 | BW020120 | BW032080 | BW035080 | BW050080 |

| Maximum load(Kg) | 22 | 68 | 90 | 147 | 158 | 227 |

| Maximum stroke(m) | 1.5 | 2.0 | 3.0 | 2.0 | 2.0 | 2.0 |

| Lifting medium | Wire rope | |||||

| Power supply | Air pressure | |||||

This is just for reference, if you need other customized feature, please contact us.

INSTALLATION WAY

1. Cantilever crane

The cantilever hanging column adopts steel pipe, and the main beam adopts I-beam; It has the advantages of simple structure, flexible operation and large working space

2.Folding arm crane

The folding arm crane is composed of a column, a rotating arm and a lifting unit. Accurate positioning, can cover multiple working units, small footprint.

3.Movable base cantilever crane

It can be moved in all directions, the operation is flexible, the positioning is accurate, and the operation range is large

4.Truss crane

The steel structure has light weight and low bearing capacity. It is suitable for transportation scenarios with limited space, height, or large travel requirements.

WORKING SCENARIO

OUR FACTORY

Contact Supplier

LINKS : Dongqi Crane