ROLLING DRUM FOR CRANE

$0.00Crane rope drum introduction

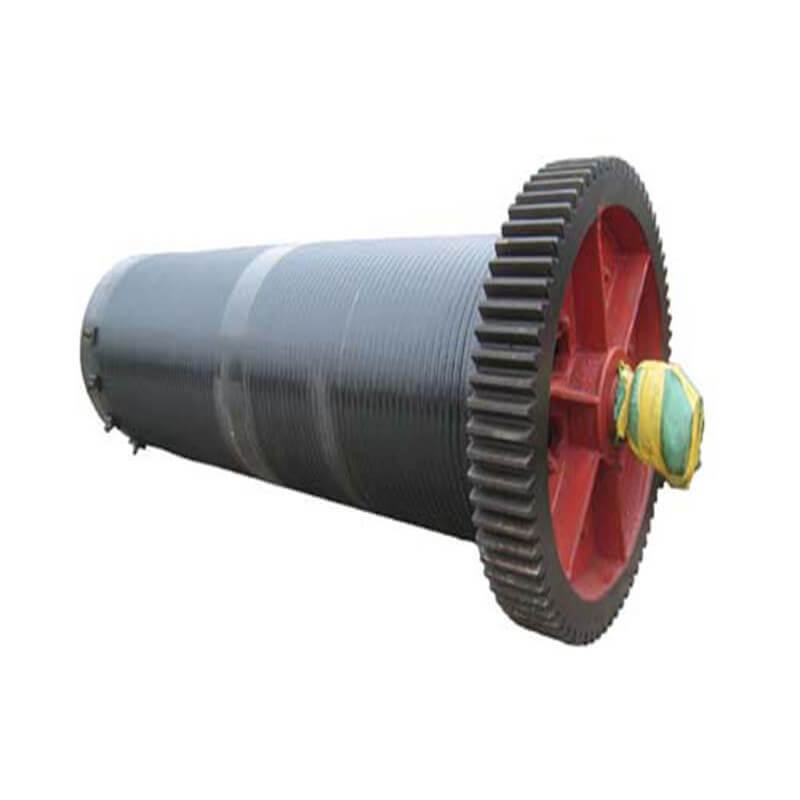

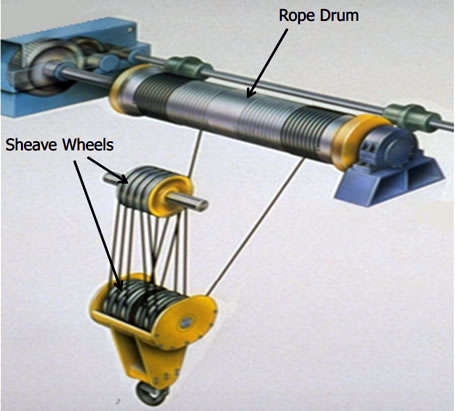

Crane rope drum is a part of crane lifting mechanism which is used to full in, entwine, and store wire rope. The rope drum is consisted of drum shaft, flange type annular gear, drum hub, bearings, bearing pedestal, etc. Every part of crane rope drum is engineered and manufactured to meet the operational and safety requirements of industrial crane applications.

Crane rope drum basic requirements

Same rules should be shared by rope seat radius, tread diameter, and the sheaves.

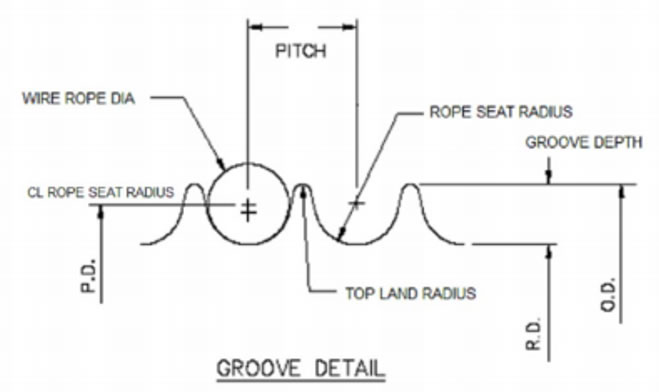

Due to rope drums have grooves, the following parameters need your attention.

Minimum pitch is 1.2 times whir rope diameter.

Groove depth is 7/16’’ * rope diameter (minimum).

The pitch and groove depth lowers the possibility of rope damage caused by sharp “fins’’ between grooves.

Sheave wheel basic requirements

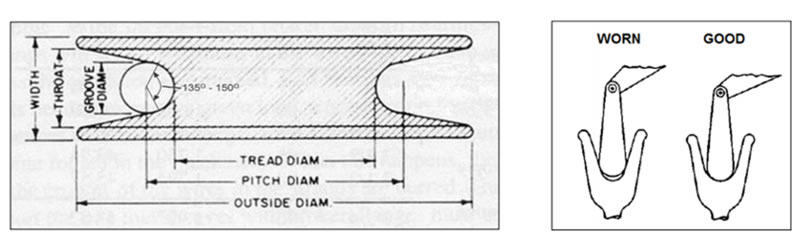

Depth of groove should be 1-0.5 times of wire rope diameter. Throat/ tread diameter is 24 to 30 times wire rope diameter.

Standard throat angle is 35°.

Rope seat radius equals to rope diameter and clearance, which should be support 135-150°of rope circumference and the surface should be slippery.

Wear can be measured with “Groove Gage”

Rope drum materials

Rope drum is usually made of cast iron. However, on special occasions or based on your special requirements, crane rope drum can directly weld with cast steel or steel plate. Customized rope drum is available from DQCRANES.

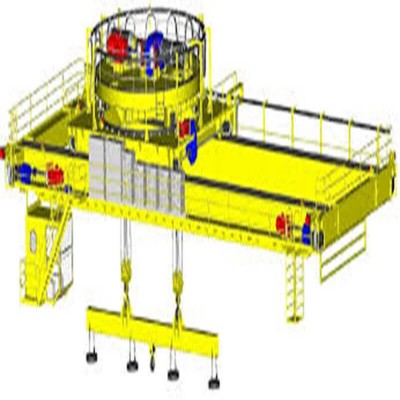

Rope drum of DQCRANES

The rope drums of DQCRANES can be used on all types of industrial cranes. We provide a wide ranges of rope drums with different sizes and designs, which can meet your cranes of any capacities. DQCRANES’ rope drum is robust, durable and reliable.

The rope drums of DQCRANES has the following advantages:

DQCRANES can produce crane parts according to customer requirements and application condition.

DQCRANES can supply the optimal rope drum for customers.

Each production procedures of each part or items is checked and supervised and recorded to ensure the quality of each part or item and each unit of equipment.

Contact Supplier

LINKS : Dongqi Crane