Electronic Scales For Crane

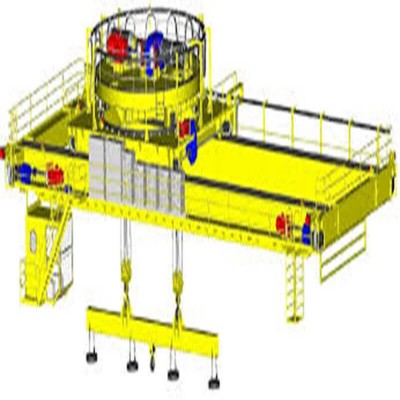

$0.00Crane electronic scale is a kind of crane weighing equipment, which is integrated with the mechanical control part of the crane to realize weighing when the crane is traveling. It uses a proximity switch to monitor the pre-determined weighing position and convert the hydraulic pressure into the weight of the load in the bucket to achieve weighing.

Principle structure characteristics of crane electronic scale

The crane electronic scale is based on the two pressure sensors installed on the oil inlet and return oil circuits of the crane boom cylinder to measure the cylinder pressure change during the crane boom lifting process, and adjust the speed. The central processor automatically calculates to obtain the weight data and displays the obtained weight on the meter screen.

During the lifting process of the crane truck, the pressure sensor transmits the signal to the computer for data conversion processing; when the locomotive shovels the cargo, the boom is immediately retracted to the starting position, and the crane electronic scale instantly displays the weight of the cargo; when the locomotive dumps the cargo, The screen displays the cumulative weight; when the tipping bucket is lowered to the starting point, the screen displays the total cumulative weight of the cargo.

The composition of crane electronic scale

Two pressure sensors, used to measure the pressure change of the crane hydraulic system;

A proximity switch, when the boom is raised to the proximity switch, the system collects pressure data;

The vehicle-mounted instrument calculates the weight data and displays the weighing result on the screen of the instrument

The crane electronic scale should be preheated when in use, and the boom should be raised 5-10 times, so that the oil pressure and sensor are preheated to normal working temperatureDuring operation, when the tipping bucket is raised, first control the joystick of the boom to be placed in the extreme rear position, that is, the tipping bucket is at the rear

The boom system should be strictly lubricated to reduce the friction coefficient of the boom

Choose a flat ground for weighing

The speed should be controlled evenly during the process of raising the boom

It is better to set zero when the crane stops moving

Avoid crane driving during the weighing process. If driving is required, the vehicle speed should be controlled at about 10KM/h

If multiple buckets are equipped, the bucket used must be calibrated when weighing

Start the crane before turning on the electronic scale, and turn off the crane power after the electronic scale is turned off

Avoid water flow such as meters when cleaning to avoid damage

Contact Supplier

LINKS : Dongqi Crane