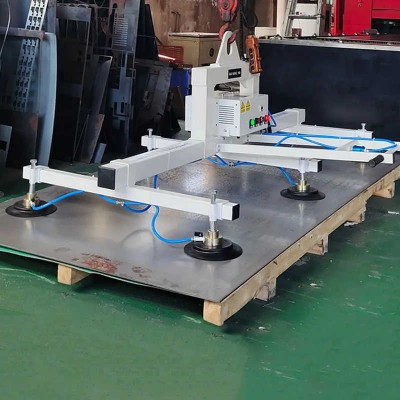

Factory Vacuum Lifting Equipment/Vacuum Lifter Machine/Glass Lifting Machine

$1200.00Product Description

Specification: (support customerized size)

Product Model : XDL-100B3M-XDL500B4M

Jib Column Size : 3300x219x6mm

Rokcer Beam Size: 4000x22mm

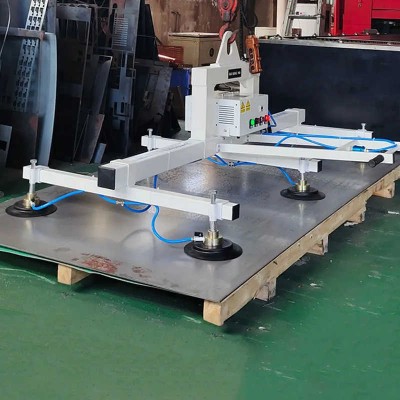

Suction Cup Equipment Size: 2000x1000mm

Cylinder Size: 1000x125mm

Color : Red/Orange/Blue/White etc

Working Area: 700~3200mm

Stroke Lifter: 1100mm

Rocker Arm Rotation: 0~270°

Max Steel Plate Size: 1500mm*3000mm/4000x2000mm(customerized size)

| Model | Carne | Rocker Arm | Strok | Capacity | Max Workpieces* | Air Pressure | Suction Pad (pcs/dia) |

| XDL-L100-B3M | 3300mm | 3000mm | 100~1100mm | 100kg | 3000mm*1500mm | 0.6~0.8Mpa | 8pcs/200mm |

| XDL-L100-B4M | 3300mm | 4000mm | 100~1100mm | 100kg | 3000mm*1500mm | 0.6~0.8Mpa | 8pcs/200mm |

| XDL-L300-B3M | 3300mm | 3000mm | 100~1100mm | 300kg | 3000mm*1500mm | 0.6~0.8Mpa | 8pcs/200mm |

| XDL-L300-B4M | 3300mm | 4000mm | 100~1100mm | 300kg | 3000mm*1500mm | 0.6~0.8Mpa | 8pcs/200mm |

| XDL-L500-B3M | 3300mm | 3000mm | 100~1100mm | 500kg | 3000mm*1500mm | 0.6~0.8Mpa | 8pcs/200mm |

| XDL-L500-B4M | 3300mm | 4000mm | 100~1100mm | 500kg | 3000mm*1500mm | 0.6~0.8Mpa | 8pcs/200mm |

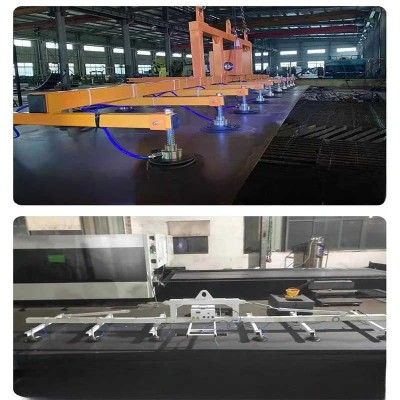

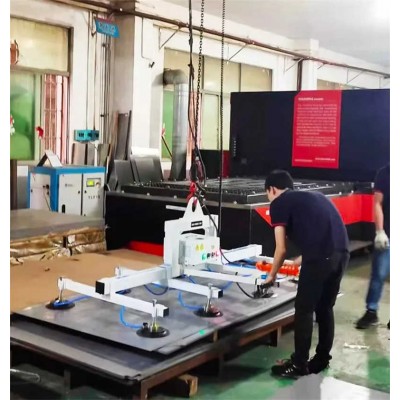

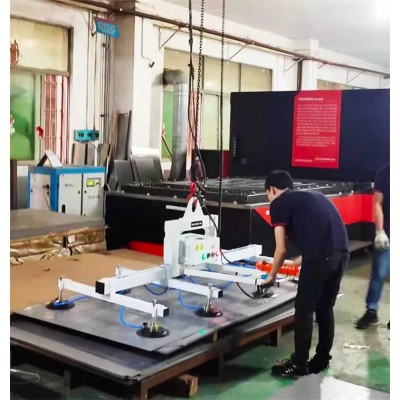

Detailed display

*Made of high-quality carbon steel and painted, with stable structure and quality assurance

*Strong load-bearing capacity, small body, large load-bearing capacity,carbon steel structure,sturdy and durable, smooth operation, long service life

*Manual valve: The original imported SNS hand valve is used to control the elevator, which is convenient and accurate in controlling the position.

*Cylinder: Purchase imported AirTac professionally designed Milan to prevent operating shock and freely control the suction cup switch.

*Load-bearing pulley: This product is our company's race pulley, which is safe for lifting operation and can safely load 100/300/500kg.

*Vacuum generator: Use original SNS vacuum generator, safe and reliable

*Regulating valve: Use original SNS pneumatic accessories regulating valve to safely and accurately adjust operating pressure.

*Suction cup: special suction cup made of imported materials, including integral hardware tools; professionally customized by our company, safe and reliable.

XINDELONG machinery plate suction crane is specially used for handling various plates and is suitable for loading and unloading of various processing machines. It has long-term cooperation with international and domestic laser cutting machine manufacturers.

*Laser cutting machine, plasma cutting machine, shearing machine loading and unloading

*Suitable for aluminum plate and stainless steel plate

*imported vacuum pumps and valves

*Maximum load 2000KG

*Accumulator and pressure detection ensure safety

*Various structures and suction cups available for configuration

*Can be applied to high temperature plates below 400 degrees

*The company passed IOS9001 and the products passed CE certification

Fast loading efficiency and cost saving

*The loading efficiency is high, and the pneumatic rocker arm loader is equivalent to the work of 6-8 workers.

Simple and easy to operate

*Using the pneumatic power-assisted principle, only need to control the button to complete the handling process of the workpiece.

*When loading materials, the operator can control the movement of the bow and arrow in space with less force, and can stop it at any position. The handling process is easy, fast and consistent.

Air cutoff protection, safety guarantee, reliable and stable, long service life

*when the air source is interrupted, the plate will remain in the original position for a period of time without falling, making it easier for the operator to remove the plate.

*The main raw materials are all produced internationally brand, Carbon steel structure, sturdy and durableand the quality is guaranteed by ISO9001 and CE certificate

Versatile to use and meet different requirement

*The position of the loading suction cup can be adjusted freely to meet different sizes of work

*Suitable for metal plates, stone slabs, wooden boards and other types of plates, easy to load

Fast Delivery & Strong Plywood Package

* Have safety semi-parts stock in warehouse, can meet delivery within 7days requirement.

*Use strong exporting standard plywood package to ensure protect machine well for long time transporation.

Installation Process Guidness

Installation Environment of Pneumatic Rocker Arm Loading Machine:

1, Ensure that the levelness of the installation ground is within ±2°.

2, Ensure that the foundation is prefabricated according to the foundation drawing provided by our company.

3, Ensure that the anchor screw position is correct.

4, The air supply pressure is within the range of 0.6-0.8MPa. (±10% or less)

5, Ensure that the installation position has enough rocker arm movement space, pay attention to the rocker arm activity area set up safety isolation belt.

Pneumatic rocker loaders require precast concrete foundations,

1,Use one end of the M20x80 threaded profile, 6 high-strength bolts with a length of 580mm, and 4 bolts with a length of 580mm, and weld them into a rectangular box (as shown in the picture)

2,Make a 2mm thick prefabricated board according to the picture, with overall dimensions: 700*700*2.

3,For prefabricated foundations, the 2mm thick prefabricated pad should be flush with the ground, and the height of the threaded section should be 60mm from the ground. The center of the anchor bolt coincides with the center of the ∅21 positioning hole on the preset gasket.

Installation of mechanical body

1, Use a truck or forklift to lift the column, adjust the position and height, and align the eight round holes on the base of the column with the eight reserved bolts on the foundation. Lay them flat and lock them tightly with M20 nuts (plus gaskets). (as shown).

Install the rocker arm

1,Use a crane or forklift to lift the rocker arm so that it is at the same level as the rocker arm fixing plate, align the screw hole of the rocker arm fixing plate and lock it with M12 screws.

2,The lifting cylinder assembly is connected to the rocker arm pulley and theconnection is firm.

The connection of pneumatic lines

1,The rocker arm needs two pneumatic connections, one (red tube) is connected to the diamond palm with adsorption function through the pressure reducing valve, and the other (blue tube) is directly connected to the lifting cylinder.

2,Connect the vacuum tubes of each sucker group.

Debugging of pneumatic rocker arm loading machine

1,Adjust the air pressure to about 0.6-0.8MPa. The pressure gauge is located on the pressure reducing valve. The automatic drainage valve in the lower part of the oil-water separation cup will automatically drain water when the pressure is low.

2,Toggle the [rise and fall] toggle switch on the control box, which can make the lifting cylinder rise and fall. The lifting and descending speed of the lifting cylinder can be adjusted by adjusting the adjusting screw on the lifting cylinder gas pipe joint. The adjusting screw at the upper end of the lifting cylinder controls the rising speed of the lifting cylinder, and the screw at the lower end of the lifting cylinder controls the falling speed.

3, moving the sucker group test suction plate. Move the sucker set to the plate, flip the [suction] switch, and check whether the pressure of the vacuum pressure gauge can reach -0.04MPa. If the pressure is lower than -0.04MPa, check whether the pipeline and switch are leaking. If the value is higher than this, it can be used normally.

Regarding to XINDELONG Machinery factory

Founded in 2021, Xindelong Machinery is the leading manufacturer of vacuum conveying technology, production auxiliary equipment and stamping peripheral equipment, and is committed to providing production solutions for industrial workshops.

Our product line includes vacuum conveying technology such as glass vacuum lifting, standard lifting, electric lifting and other standard or custom equipment, widely used in sheet metal, stone, wood, plastics and other fields; Stamping peripheral auxiliary equipment, such as automatic feeding, transmission, etc., is widely used in laser, sheet metal and other related industries.

Since the establishment of the company, through pragmatic, unremitting efforts; With high quality service and competitive price, the products are exported to the Middle East, Southeast Asia, Eastern Europe and other countries.

Contact Supplier

LINKS : Dongqi Crane