30 Ton European Type Double Girder Overhead Crane Supplier

$12000.00Product Description

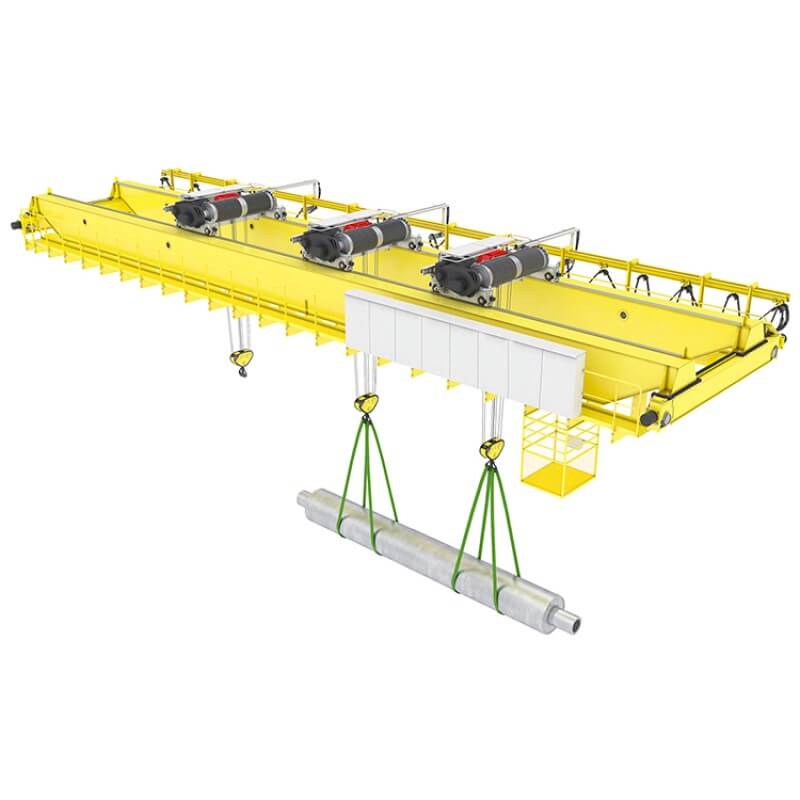

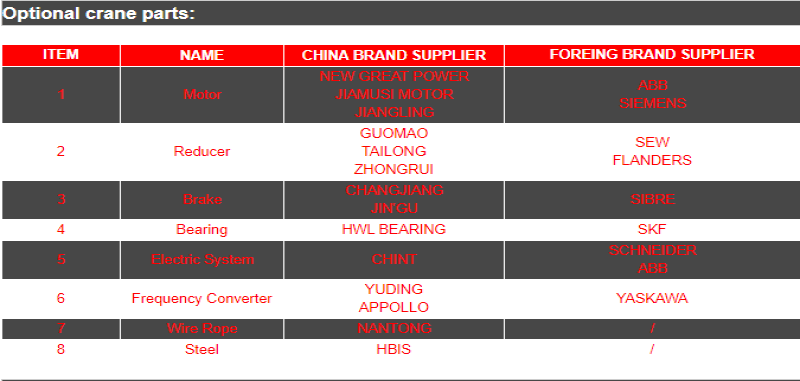

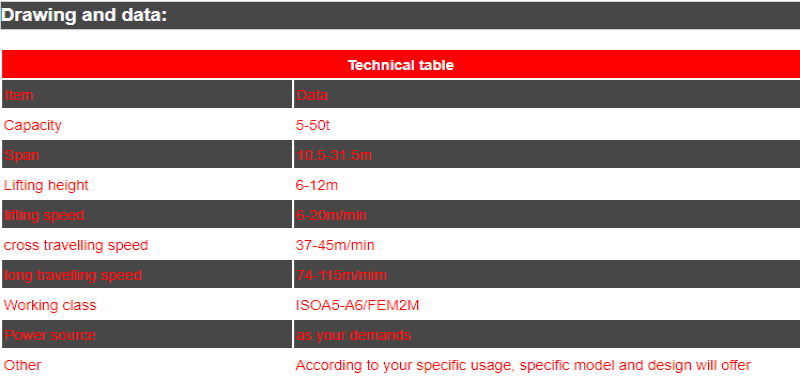

30 ton European type double girder overhead crane supplier is composed of box type bridge frame, lifting trolley, crane traveling mechanism, and electrical system. It is an excellent choice where high speeds and heavy service are required. As the widely used hoisting machinery currently especially is suitable for working at warehouses and freight yard and other department it is prohibited to use the equipment in the combustible, explosive or corrosives environment.

It is rely on the bridge frame along the workshop orbital direction moving longitudinal, the trolley along the main beam direction moving transverse and the hook lifting movement to work. High lifting capacity of this crane is designed with two hooks that means two independent sets of hoisting mechanism. The main hook is used to lift heavy objects while the auxiliary used to lift light objects,the auxiliary can also be used for collaborative main hook tilting or tipping the material. However, don’t use the two hooks to lift at the same time when goods weight is over the auxiliary rated capacity.

Advantage

1. Overload protection: If the material is over the capacity, the crane will give a sharp warning for protection itself

2. Emergency brake: If the operation staff encounter some emergency situation, we could start the emergency brake system to protection the related treasure.

3. Control Method: Room control or remote control to avoid any injure to the operation staff

4. Main lifting motor: with thermal protection and currency protection.

5. Hooks with latch

6. Rubber buffers

7. Protective earthing

8. Crane switch and travel end switch

9. Sub-assemblies characteristic are tested before assembly.

10.All cranes must be pre-assembled and tested before leaving factory and offer the certification of test.

Processing

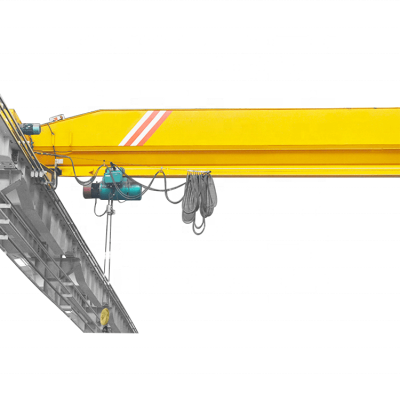

Overhead Crane Control Method

1.Wireless Remote control

2. Pendent control

3.Cabin Control

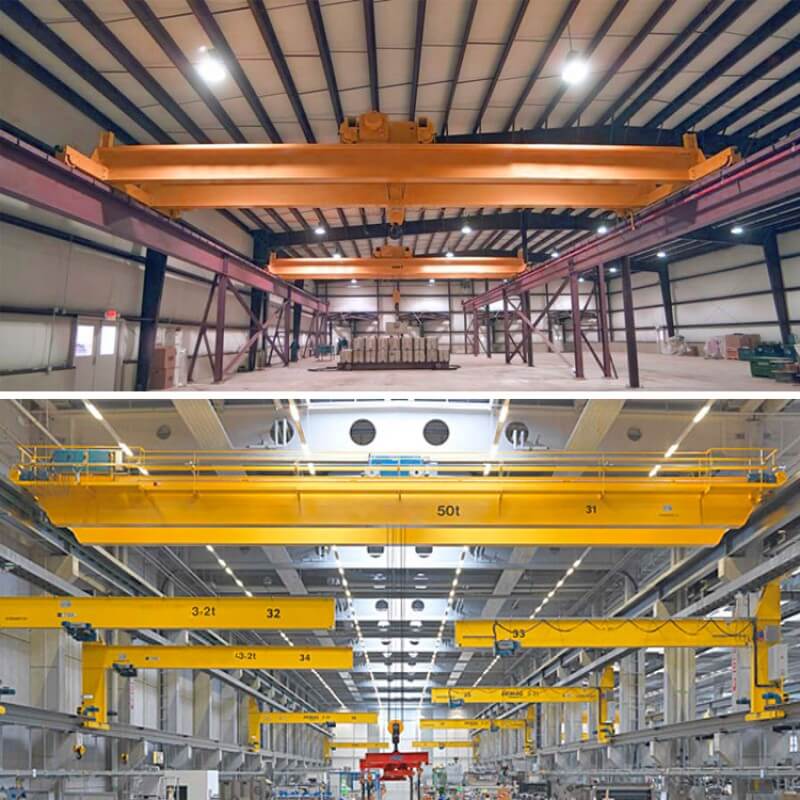

Application

Contact Supplier

LINKS : Dongqi Crane